Chicken wire netting machine

Hexagonal Chicken Wire Netting machine

Hexagonal wire netting machine is also called chicken wire fence machine, which is used to weave the hexagonal mesh with 6 twist (positive and negative twist) .

Our hexagonal mesh machine is full automatic production line for wire feeding, wire twisting and mesh rolling. Raw material of the machine can be galvanized wire and pvc coated wire.

Chicken Wire Netting machine Parameter:

| Model | DP-CSR-3300 |

| Wire thickness | 0.50-2.0mm |

| Mesh size | 1/2’’, 1’’, 2’’, 3’’… can be customized as you want |

| Mesh width | 2.6M, 3.3M, 4M, 4.3M (customized as you want) |

| Weaving speed | 1/2’’ mesh size, 60-65M/hour

1’’ mesh size, 95-100M/hour 2’’ mesh size, 150-160M/hour 3’’ mesh size, 180M/hour |

| Wire material | Galvanized wire, pvc coated wire |

| Motor capacity | 2.3kw+2.3kw+2.3kw+4.4kw+0.75kw |

| Number of Twists | 6 |

| Machine Weight | 3.6T |

| Note: one set machine can only do one mesh size | |

Chicken Wire Netting machine Video:

Chicken Wire Netting machine Advantages:

|

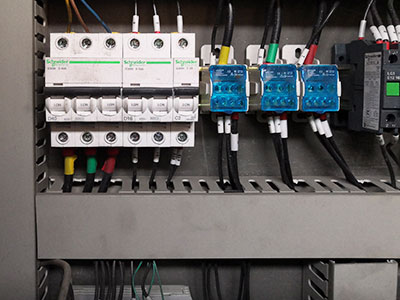

1. PLC+touch screen, Schneider electric parts, easy to operate. |

|

|

|

|

|

2. Single-step control button. |

3. Yellow steel cover for safety protection when machine working. |

|

|

|

|

4. When wire is broken or finished, the machine will alarm and stop automatically. |

5. Four servo motors to control four parts, working more stable. |

|

|

|

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Equipment maintenance

|

A. Don't remove any cable from electrical cabinet to the motor. B. Add oil to the bearing/gear part every week/shift. |

Certification

Hexagonal chicken netting application

Hexagonl wire mesh is popular used for husbandry, fencing, protection, construction, farming etc.

FAQ:

1. What's the delivery time of the machine?

About 40 days after receiving your deposit.

2. What are the payment terms?

30% T/T in advance, 70% T/T before shipment, or L/C, or cash, etc.

3. What's the package of the machine?

One set 3.3M machine can be loaded in one 20-foot container in bulk and free spare parts will be in carton/wooden box.

4. If the machine can weave two/three nets mesh at the same time?

Yes, the machine can weave several nets mesh at the same time. For example, one 3.3M set machine can weave three nets of 1M mesh or two nets of 1.5m mesh at the same time.

5. How long of the guarantee time?

One year since the machine was installed at the buyer's factory but within 18 months against the B/L date.