CNC gabion machine for sale

Description of CNC gabion machine

Since its introduction in 2024, the DAPU CNC gabion machine has been deeply loved by users for its simple operation and ultra-high output (approximately 10,000-15,000 square meters/10 hours), and now occupies 80%-90% of the market both domestically and internationally.

This metal weaving equipment completely solves the problems of high labor costs, low production efficiency, and poor mesh accuracy associated with traditional equipment. At DAPU, you not only get a machine, but also thirty years of accumulated patented technology support and stable, efficient production assurance.

Advantages of CNC gabion machine

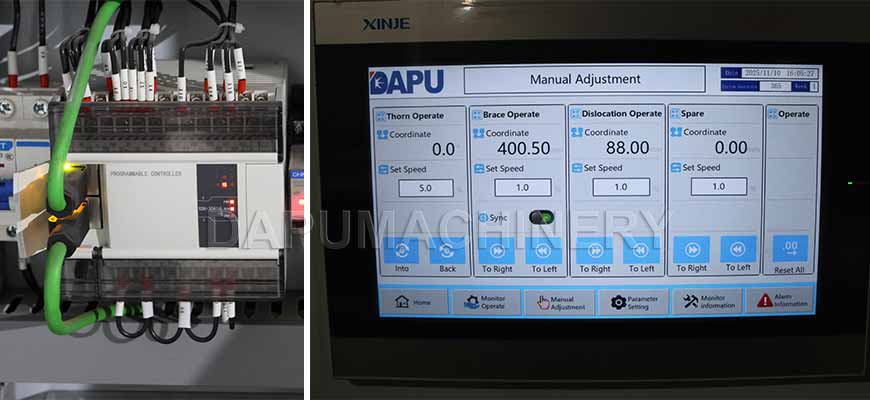

1. DAPU gabion mesh making machine adopts CNC control, the twist number and twist length can be set on the touch screen.

2. Three servo motors control three parts respectively, so the machine can work stably with high speed, about 10000-12000 square meters/day, which is double that of the normal mechanical type machine.

3. A machine equipped with 4 racks, all of which are working, similar to a 4-wheel drive car with big power. So it can weave 4 nets 1M mesh at the same time, the wire diameter can be max. 4mm (the mechanical machine can only handle 3.5mm).

4. Automatic lubrication system, the lubrication system is equipped with an automatic oiling device, controlled by a 0.75 kW motor for continuous lubrication, and easier maintenance.

5. The DAPU gabion machine is easy to operate and does not require workers with rich experience.

Specification of CNC gabion machine

| Model | DP-LNWL-5300H |

| Wire diameter | 1.5-4.0mm |

| Mesh Size | 60*80mm,70*90mm, 80*100mm, 90*110mm, 100*120mm, 110*130mm, 120*140mm, 130*150mm etc. |

| Mesh Width | Max.5300mm |

| Twist number | 3 or 5 can be set on the touch screen |

| Twist length | 3 twist, 30-55mm can be adjusted 5 twist, 45-70mm can be adjusted |

| Motor capacity | 22kw+15kw+11kw+0.75kw |

| Working capacity | 10000-15000㎡/10hours For a 90*110mm opening can be 12000㎡/10hours |

| Dimension | 10*1.8*3.5M |

| Weight | 16T |

Video of CNC gabion machine

Application of gabion mesh

1. Water Conservancy Project Protection

Riverway Management

Flood Control and Anti-scour

2. Ecological Restoration and Soil and Water Conservation

Ecological Bank Protection

Water Purification

3. Road and Landscape Construction

Roadbed Protection

Landscaping

Sales-after service

Welcome to the DAPU Factory

We welcome global clients to schedule a visit to DAPU's modern factory. We offer comprehensive reception and inspection services.

You can initiate the inspection process before equipment delivery to ensure that the fully automatic gabion machine you receive fully meets your standards.

Providing Guidance Documents

DAPU provides operation manuals, installation guides, installation videos, commissioning videos, and other guidance documents to help clients learn how to operate the fully automatic gabion mesh machine.

Overseas Installation and Commissioning Services

DAPU will dispatch technicians to the client's factory for installation and commissioning, train workshop workers to operate the equipment proficiently, and quickly master daily maintenance skills.

Regular Overseas Visits

DAPU's highly skilled engineering team visits client factories overseas annually to maintain and repair equipment, extending equipment lifespan.

Rapid Parts Response

We have a professional parts inventory system, enabling us to respond quickly to parts requests within 24 hours, reducing downtime and supporting global clients.

CE & ISO certification

DAPU wire mesh welding machines are not merely high-performance rebar mesh production equipment, but also a showcase of innovative technology. We hold CE certification and ISO quality management system certification, meeting stringent European standards while adhering to the highest international quality management standards.

Exhibition

DAPU's active presence at global trade shows showcases our strength as a leading wire mesh machinery manufacturer in China.

At the China Import and Export Fair (Canton Fair), we are the only qualified manufacturer in Hebei Province, China's wire mesh machinery industry, to participate twice a year, in both the spring and autumn editions. This participation symbolizes the nation's recognition of DAPU's product quality, export volume, and brand reputation.

In addition, DAPU participates in international trade shows annually, currently exhibiting in over 12 international markets, including the United States, Mexico, Brazil, Germany, the UAE (Dubai), Saudi Arabia, Egypt, India, Turkey, Russia, Indonesia, and Thailand, covering the most influential trade shows in the construction, metal processing, and wire industries.

FAQ

Q: What container is needed for loading the gabion machine?

A: The main mesh machine needs one 40 OT container for loading.

Q: What raw materials are suitable for the gabion machine?

A: The machine is suitable for galvanized wire and PVC-coated wire.

Q: Can we make different opening sizes with one set of gabion machines?

A: No, one set of machines can only do one mesh opening size.

Q: How can we change the twisted length and twisted number?

A: Can be set on a touch screen easily.

Q: How many people need to operate the gabion machine?

A: Two or three persons.

Q: What maintenance is required for the gabion machine?

A: Gearbox lubricant should be changed regularly; the Net class front seat and the parts should be lubricated.