Wire Mesh Cable Tray Welding Machine

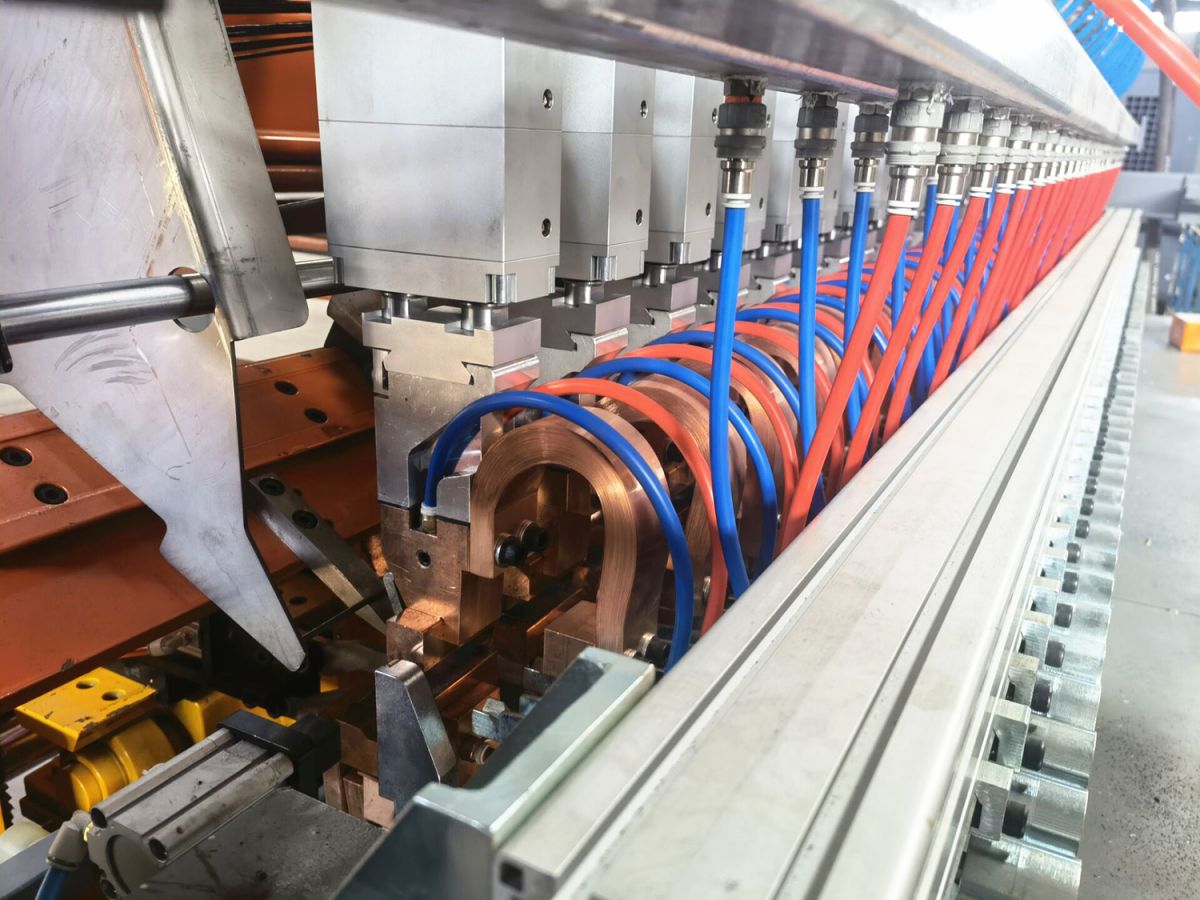

DAPU cable tray welding machine equipped SMC 45 quadruple-force&energy-saving air cylinder, higher welding power, lower energy cost;

Line wire be pre-straight& cut, and feeding to the car, while last mesh panel nearly finished welding, next mesh panel wires will be feed to the welding part automatically, save time;

The cross wire feeder can feed two cross wires at same time, then can make two mesh one time.

Panasonic servo motor control mesh pulling car, which is faster and accurate;

Each part of this DAPU wire mesh cable tray welding machine cooperates efficiently and has reached the high-speed welding level of 150 times/min, helping you greatly increase production;

Machine Parameter:

| Model | DP-FP-1000A+ |

| Wire diameter | 3-6mm |

| Line wire space | 50-300mm |

| Allow two 25mm | |

| Cross wire space | 12.5-300mm |

| Mesh width | Max.1000mm |

| Mesh length | Max.3m |

| Air cylinder | 10pcs for max.20 points |

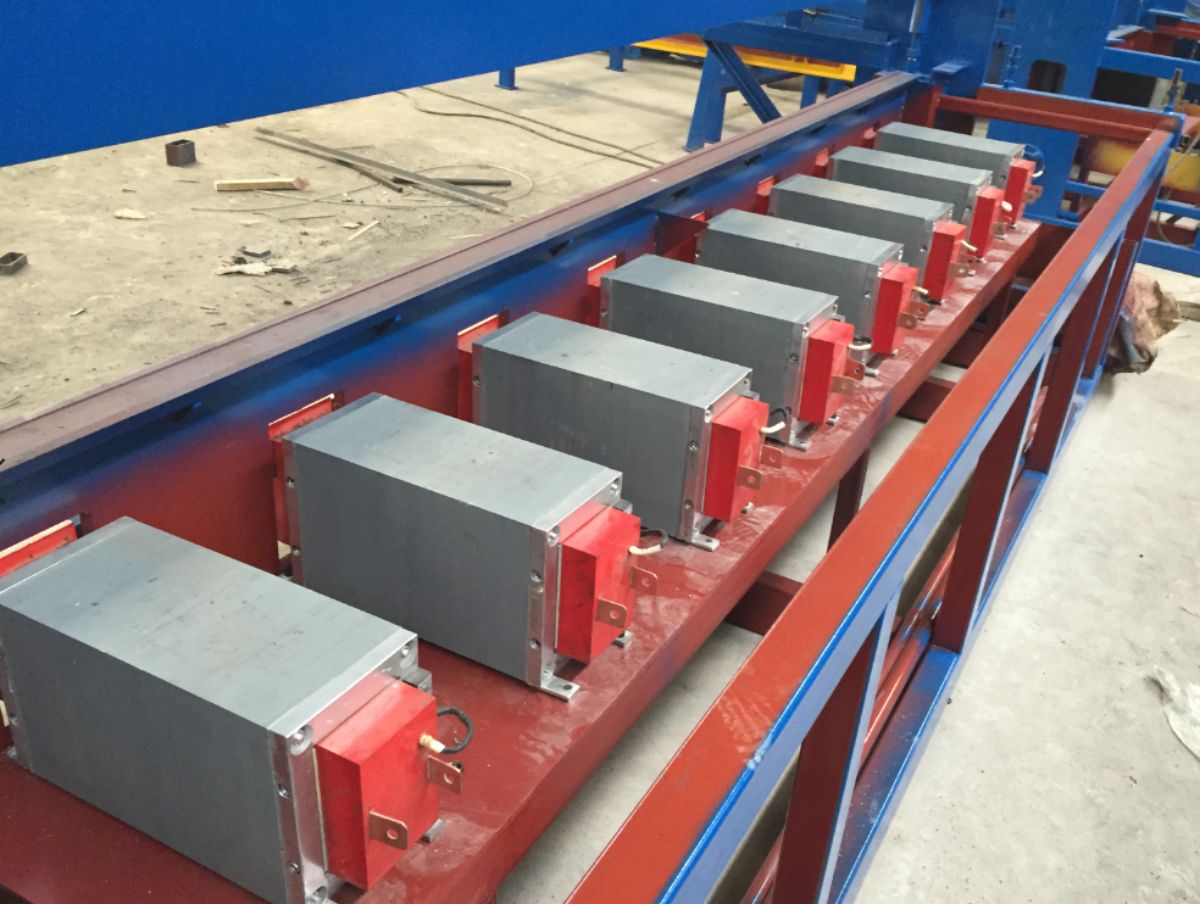

| Welding transformer | 150kva*4pcs |

| Welding speed | Max.100-120 times/min |

| Wire feeding way | Pre-straightened&pre-cut |

| Weight | 4.2T |

| Machine size | 9.45*3.24*1.82m |

Can be customized according to your requirement;

Accessory equipment:

GT3-6H Wire Straightening& Cutting Machine

Bending Machine

Wire mesh cable tray Application

In the electrical wiring of buildings, a cable tray system is used to support insulated electrical cables used for power distribution, control, and communication.

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

A:Lubrication liquid is added regularly.

B:Checking electric cable connection every month.

Certification

FAQ

Q: How much space required for this cable tray production line?

A: Engineer will design the layout for you specially according to your requirement;

Q: For making wire mesh cable tray, what else equipment should i buy with welding machine?

A: Wire straightening& cutting machine, cable tray bending machine; rest is chiller and air compressor as welding machine accessories;

Q: how much labor required for your machine?

A: 1-2 is ok;