Fully automatic nail making machine

A wire nail has a head and a shank integral with the head, the shank being formed with a tip and having an axis, and the head having a circumferential edge defining a complete circle; characterized in that the center of the head is radially offset from the axis of the shank.

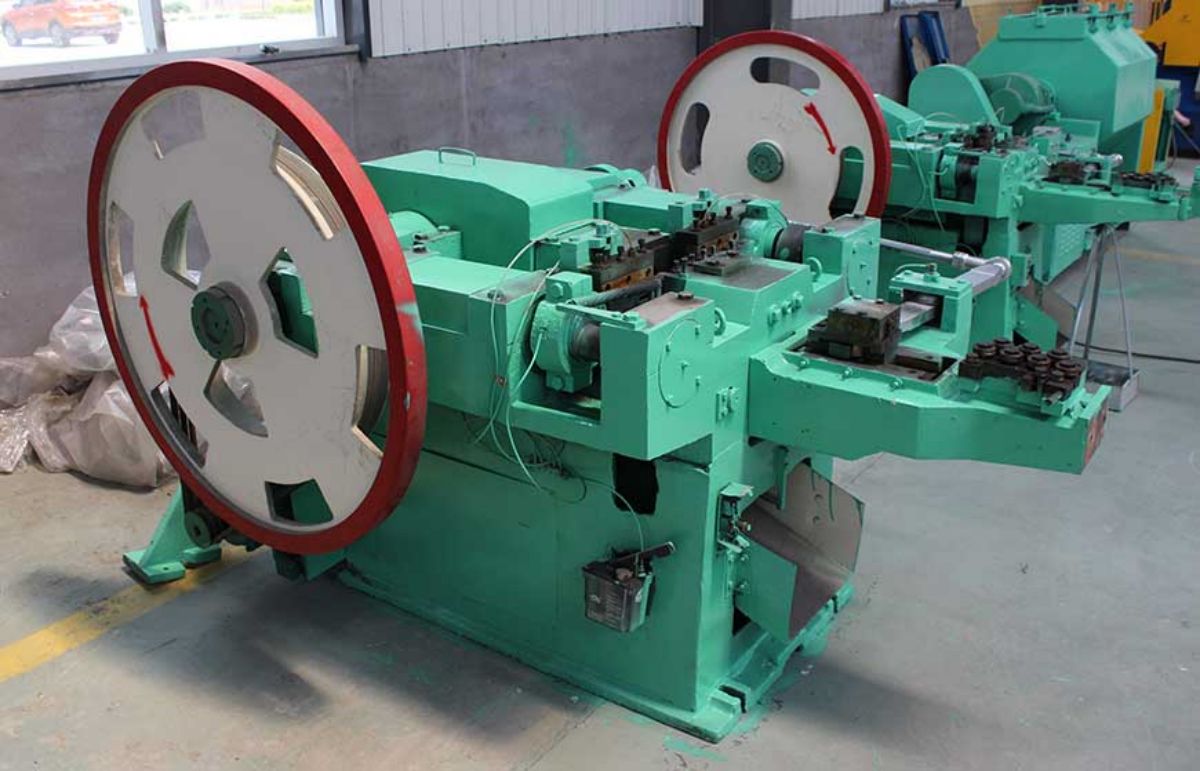

Common nail making machine

High speed nail making machine

Common nail making machine parameter:

| MM | Capacity(pieces/min) | Motor (KW) | Dimension (MM) | Weight (KGS) | ||

| Wire diameter | Nail length | |||||

| Z94-1C | 0.9-1.6 | 9-25 | 450 | 1.5 | 1440*1040*1270 | 1200 |

| Z94-2C | 1.2-2.8 | 16-50 | 350 | 2.2 | 1670*1240*1380 | 1400 |

| Z94-3C | 1.8-3.4 | 30-75 | 320 | 3 | 1830*1300*1470 | 1100 |

| Z94-4C | 2.8-4.5 | 50-100 | 280 | 4 | 2130*1560*1580 | 2000 |

| Z94-5.5C | 3.7-5.5 | 80-150 | 200 | 5.5 | 2500*1600*1700 | 2500 |

High speed nail making machine parameter:

| Model | DP-X50P | DP-X90P | DP-X130P | DP-X150P |

| Wire diameter | 1.8-2.5mm | 2-3.5mm | SS steel 2.5-4.8mm | SS steel 2.5-4.8mm |

| Low carbon 2.5-5.2mm | Low carbon 2.5-5.5mm | |||

| Nail Length | 32-64mm | 32-92mm | 50-130mm | 70-150mm |

| Speed | 800pcs/min | 760pcs/min | 650pcs/min | 500pcs/min |

| Motor | 5.5kw+1.5kw | 5.5kw+1.5kw | 7.5kw+2.2kw | 11kw+2.2kw |

| Dimension | 1500*950*1300mm | 1500*1180*1100mm | 1540*1160*1300mm | 1650*1200*1300mm |

| 1600*900*1650mm | 1600*900*1650mm | 1600*900*1650mm | 1600*900*1650mm | |

| 420*760*970mm | 420*760*970mm | 420*760*970mm | 420*760*970mm | |

| Weight | 2500kg | 2800kg | 4200kg | 4500kg |

Nail making machine Advantages:

Good brand electronic components

1.Delta brand PLC

2.Delta Touch screen

3.Schneider power supply

4.Schneider air switch and relay

5.Inovance Inverter

6.Omron sensor

High productivity

The machine has high stability, and the speed can reach 760 pieces/minute; it can save a lot of labor and increase production capacity (the production capacity can be more than doubled under the same site and manual work).

High stability

Our nails making machine have good stability, double molds and double punches, and two moldings. The machine is equipped with long and short nail sensor, automatic turning machine function, no waste, which ensures the quality of nail making.

Finished Product:

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Certification

FAQ

Q: What are the accepted payment methods?

A: T/T or L/C is acceptable. 30% in advance, we start produce machine. After machine finished, we will send you testing vide or you could come to check machine. If satisfied with machine, arrange balance 70% payment. The we can loading machine to you.

Q: How to transport different type of machine?

A: Normally 5 set of machine need one 20GP container. Single one need to packing in wooden box sending by LCL.

Q: The production cycle of the razor barbed wire machine?

A: About 20 days

Q: How to replace worn parts?

A: We have free spare part box loading together with machine. If there is other parts needed, normally we have stock, will send to you in 3 days.

Q: How long is the warranty period of the razor barbed wire machine?

A: 1 year after the machine arrive in your factory. If the main part broken because of quality, not manually mistake operation, we will send you replace part for free.

A: T/T or L/C is acceptable. 30% in advance, we start produce machine. After machine finished, we will send you testing vide or you could come to check machine. If satisfied with machine, arrange balance 70% payment. The we can loading machine to you.

Q: How to transport different type of machine?

A: Normally 5 set of machine need one 20GP container. Single one need to packing in wooden box sending by LCL.

Q: The production cycle of the razor barbed wire machine?

A: About 20 days

Q: How to replace worn parts?

A: We have free spare part box loading together with machine. If there is other parts needed, normally we have stock, will send to you in 3 days.

Q: How long is the warranty period of the razor barbed wire machine?

A: 1 year after the machine arrive in your factory. If the main part broken because of quality, not manually mistake operation, we will send you replace part for free.