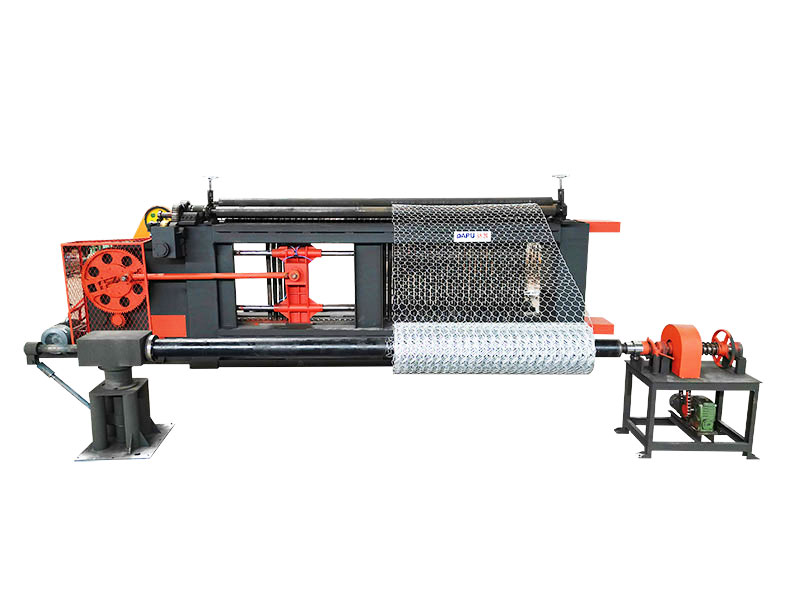

Gabion Mesh Machine

Gabion Mesh Machine

● long service live, at least 10 years

● Highly production

Gabion machine, also named gabion box machine, stone cage machine... etc.; is used to produce hexagonal mesh as a stone box, for protecting coastlines, river banks, and slopes from erosion;

This gabion machine consists of 4 parts: wire spiral machine, wire tension device, main weaving machine, mesh roller;

Also, we can provide the auxiliary equipment as a complete production line for making gabion boxes, such as mesh cutting machine, border selvage machine, packing machine...etc;

How to choose a gabion mesh production line?

For making hexagonal mesh roll only, then just choosing the main gabion machine with the necessary 4 parts is okay;

For making a stone cage, besides the gabion machine 4 parts, you still need to buy a border selvage machine, bending machine, packing machine;

Or send an inquiry with your requirements, and we will provide a suitable solution for you.

Machine Advantages:

| 1. PLC+ Touch screen control system, user friendly;

|

2. Schneider electrical components;

|

| 3. Special designed device to recycle lubricating oils, easy to maintain machine.

|

4. Wheel core with cast steel can well improve the toughness and wear resistance, the same as Italy machine.

|

5. Double welding cross beam and 12mm thickness bottom plate, shock-resistance, strong reinforcement. |

6. Copper bush to decrease wearing out under main machine continuous working. |

|

Cam made of nodular cast iron to increase wear resistance.

|

Our dragging plate made of nodular cast iron is with a lining. So, it is not easy to wear out. Its life is long.

|

Machine Video:

Machine Parameter:

|

Model |

DP-LNWL 4300 |

|

Wire diameter |

1.6-3.5mm |

|

Selvedge wire diameter |

Max. 4.3mm |

|

Grid size |

60*80/ 80*100/ 100*120/ 120*150 mm Note: each set machine only can make single grid size |

|

Mesh width |

Max. 4300 mm Can make several rolls at same time |

|

Motor |

22 kw |

|

Production |

60*80mm-- 165 m/ hour 80*100mm-- 195 m/ hour 100*120mm-- 225 m/ hour 120*150mm-- 255m/ hour |

|

Also can be customized according to your specifications; |

|

Accessory Equipment:

|

Top drawing wire reel pay off stand |

wire spiral machine |

Wire tension device |

mesh roller |

|

|

|

|

|

|

Mesh cutting machine |

Mesh boarder selvedge machine |

Packing machine |

Wire straightening& cutting machine |

|

|

|

|

|

Gabion Mesh Application:

Gabion mesh can used in retaining wall structures, river and canal training, Erosion and scour protection; roadway protection; bridge protection, Hydraulic structures, dams, and culverts, Coastal embankment works, Rockfall and soil erosion protection, Architectural cladding for walls and buildings, Freestanding walls, noise and environmental barriers, Architectural Gabion Applications, Military defences, etc.

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Equipment maintenance

|

A. Lubrication liquid is added regularly. B. Checking electric cable connection every month. |

Certification

FAQ

Q: What’s your delivery time?

A: For this gabion machine, normally is 45 working days after receiving your deposit;

Q: How much labor required for gabion machine?

A: Two workers.