Expanded metal has a wide range of uses and is in great demand. Construction, industry, decoration, and other industries cannot do without it! Want to efficiently produce high-quality expanded metal? Dapu expanded metal machine is your ideal choice! Simple operation, high output, and low cost help you quickly seize the market and make money easily!

Characteristics of Expanded Metal:

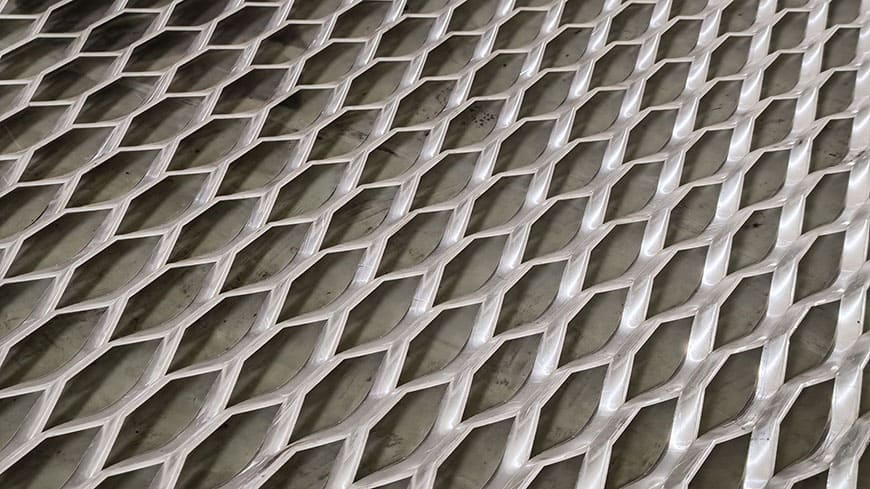

Expanded mesh is formed by punching and stretching metal plates/coils through expanded mesh machines. It has high structural strength and strong pressure and impact resistance. Hollow design and light weight save 30%~50% of materials compared to solid steel plates, reducing transportation and installation costs. In addition, the shapes of expanded mesh are diverse, such as diamond, hexagon, fish scale holes, etc., so it has good air permeability, light permeability, and Ventilation. The expanded mesh has strong friction and high anti-slip properties. Moreover, the expanded mesh has strong durability and corrosion resistance, and can be used in various harsh environments. Especially after galvanizing, the service life can reach more than 20 years, and the maintenance cost is extremely low.

Expanded metal mesh has a wide range of applications, including:

Construction industry: concrete reinforcement, exterior wall decoration, safety fence, exterior wall scaffolding pedal, etc.

Transportation and infrastructure: highway/railway fence, bridge walkway network, airport fence, etc.

Industrial manufacturing: filter screens, anti-skid plates, equipment protection cover, oil platform walkway, sewer protection fence, etc.

Home decoration: creative furniture, art installations, hollow ceilings, stair step anti-skid plate, storage rack, art partition, restaurant/park tables and chairs, etc.

Agriculture and animal husbandry: farm fence, etc.

With the acceleration of urbanization and industrial upgrading, the demand for expanded metal has been rising year by year. Investing in expanded metal production equipment means seizing the future market!

DAPU expanded metal machines – efficient production, stable, and reliable

Our machine adopts advanced CNC technology and high-strength molds, with the following core advantages:

1. High-precision stamping and stretching

Motor control ensures uniform hole shape and high tensile strength. Different hole shapes can be customized to meet diverse needs.

2. High-efficiency production

Automated feeding, stamping, and collection are integrated to greatly increase production capacity. Support a variety of plate thicknesses to meet different specifications.

3. Energy saving and material saving

Optimize the stamping process and no waste is generated.

Low energy consumption design saves 30% energy compared to traditional equipment.

4. Intelligent control and easy management

PLC CNC system, touch screen operation interface, adjustable parameters, simple and easy to learn.

Win-win cooperation-dapu provides you with all-round support

Choosing DAPU is not only buying a expanded metal mesh machine, but also getting a long-term partner! We provide:

Customized solutions-recommend the most suitable model according to your needs.

Technical training-on-site installation and commissioning, and free training for operators.

Lifelong maintenance-24-hour after-sales response to ensure the continuous and efficient operation of the equipment.

Post time: Jun-26-2025