1. What Is a Clear View Fence Welding Machine?

Clear view fence welding machines are fully automated welding equipment specifically designed for producing high-security clear view fence panels (anti-climb fences).

This type of fence offers the highest level of security, characterized by its difficulty to climb and cut, forming a robust physical barrier. It is primarily used for security fencing in countries like South Africa and Zimbabwe.

Clear view fences are formed by welding 3-6mm steel wire, with mesh sizes typically 12.7mm x 76.9mm. Almost no tools can break it, and there are no footholds for climbing.

1.1 Clear View Fence / Anti-Climb Fence – Local Names in Southern Africa

In different African markets, Clear View Fence systems are commonly referred to by several names:

- Clear View Fence – the most common term in South Africa

- Anti-Climb Fence – widely used in both South Africa and Zimbabwe

- High Security Fence

- Prison Fence

- Security Mesh Fence

Manufacturers of safety fences will purchase anti-climb welding machines to produce high-precision, high-weld-strength, and high-safety-standard clear view fences to meet local security requirements.

1.2 How Is a Clear View Fence Welding Machine Different from Standard Fence Welding Machines?

Compared to ordinary security fence welding machines, the Clear View Fence Machine is specifically designed for producing high-security metal fences:

Smaller mesh openings, making them harder to climb;

Higher weld strength, making them harder to cut with tools;

Pneumatic welding technology ensures consistent electrode pressure, resulting in strong welds and a smooth mesh;

A robust frame structure allows for continuous production over extended periods;

DAPU’s professional Clear View Fence Machine ensures that the produced metal panels meet the needs of African markets such as South Africa and Zimbabwe.

2. Why Clear View Fences Are Widely Used in South Africa & Zimbabwe?

With the growing demand for security, theft prevention, and durable fencing in South Africa and Zimbabwe, clear view fences have become the top choice for high-security fencing.

Unlike other metal fences, clear view fences offer a high-definition view while being extremely difficult to climb, a feature that attracts many high-security locations.

2.1 High Demand for Security Fencing in South Africa

South Africa’s demand for high-security fencing solutions is increasingly strong, especially in the following locations:

- Residential estates and gated communities

- Industrial parks and warehouses

- Power substations and utilities

- Schools, hospitals, and public facilities

The popularity of clear view fences in South Africa and Zimbabwe stems primarily from their ability to provide maximum surveillance visibility while preventing climbing. Therefore, local metal fence manufacturers are constantly seeking and sourcing anti-climb fence machines to meet market demand.

2.2 Clear View Fence Applications in Zimbabwe

In Zimbabwe, Clear View Fences are commonly used in:

- Mining sites and resource facilities

- Government and institutional projects

- Infrastructure and border security applications

These projects typically require robust fence panels capable of standing harsh environments and long service life.

2.3. Advantages of Clear View Fences Over Traditional Fencing Systems

Compared with chain link fences or standard welded mesh fences, Clear View Fences offer clear advantages in Southern African markets:

- Anti-climb design with narrow vertical wire spacing

- High welding strength for improved security

- Excellent visibility for camera and guard monitoring

- Low maintenance costs over long-term use

These benefits explain why Clear View Fences are increasingly specified in South African and Zimbabwean security fencing projects, driving continuous demand for professional security fence welding machines designed specifically for anti-climb fence production.

3. Production Challenges for Clear View Fence Manufacturers

With the continued growth in demand for high-security fencing, the requirements for the precision and quality of clear view fence specifications are becoming increasingly stringent. Manufacturers of clear view fences in South Africa and Zimbabwe often face the following problems:

3.1 Inconsistent Welding Quality

Clear view fences require strong and uniform welds to meet anti-climb and anti-cut requirements.

However, due to outdated equipment or lack of expertise, manufacturers frequently encounter inconsistent welding quality, leading to insufficient weld strength and inaccurate fence specifications.

This problem is particularly critical when supplying fences for government, mining, or infrastructure projects.

3.2 Low Production Efficiency

Manual or semi-automatic welding equipment significantly limits output.

As order volumes increase, factories struggle to sustain low production efficiency, making on-time delivery difficult and resulting in missed large project orders.

Without automated clear view fence welding machines, scaling up production becomes both slow and inconsistent.

3.3 High Labor Costs and Dependence on Skills

The production of clear view fences requires precise wire alignment and consistent welding; semi-automated production equipment typically relies on experienced operators.

In Southern Africa, rising labor costs and increased personnel turnover have increased operational risks, leading to higher labor costs per fence panel and less consistent product quality.

3.4 Inconsistent Wire Spacing and Insufficient Fence Panel Precision

One of the most common technical problems is large errors in wire spacing, which directly affect the qualification of the fence panels.

Even minor deviations can cause fence panels to fail to meet safety specifications or be rejected during project acceptance.

3.5 Difficulty in Meeting Bidding and Project Specifications

Many security fencing projects in South Africa and Zimbabwe are based on stringent bidding specifications, including wire diameter, mesh spacing, weld strength, and fence panel flatness.

Manufacturers using general-purpose welding machines often struggle to meet bidding specifications, thus reducing their competitiveness.

By clearly understanding these production challenges, manufacturers can understand why investing in a dedicated high-safety fence welding machine is no longer an option but a necessity for sustainable development in the Southern African security fencing market.

4. Automatic Clear View Fence Welding Machine Solution

This fully automated clear view fence welding machine is designed specifically for producing high-security, anti-climb fence panels, featuring high weld strength, high stability, high precision, and high production efficiency.

This solution is tailored for clear view fence manufacturers in South Africa and Zimbabwe, helping them meet security fence specifications while reducing labor costs and increasing output.

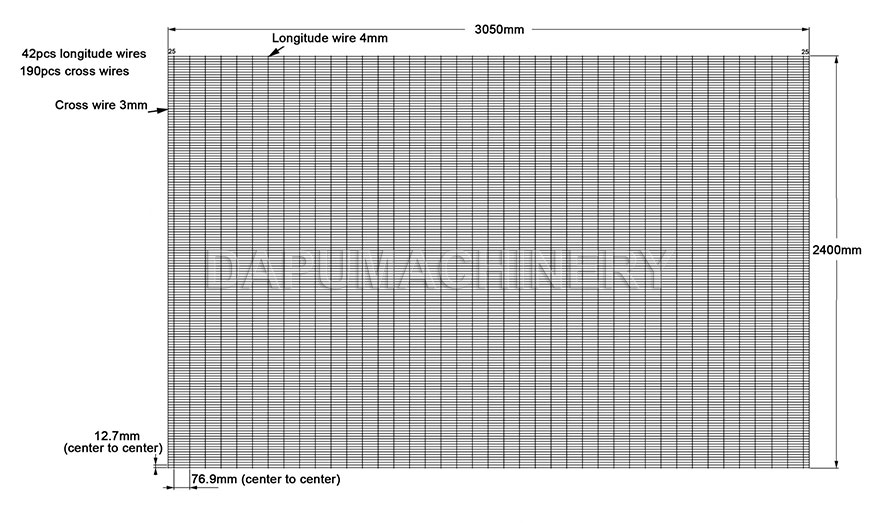

4.1 Clear View Fence Parameters

DAPU High-Security Fence Welding Machine Configuration meets the most common clear view fencing needs in Southern Africa:

Wire Diameter: 3-6 mm

Suitable for standard and heavy-duty anti-climb fence panels

Wire Feeding System:

Line and cross wire pre-straightened & cut, precise wire feeding

Mesh Size:

Fully customized according to South African clear view fence standards and project specifications, typical mesh size is 12.7mm x 76.9mm

Welding System:

This equipment uses pneumatic welding technology and servo-controlled mesh pulling to ensure strong and uniform welds

Output:

Optimized output in the number of fence panels per hour, designed for continuous industrial production

These structured configurations ensure consistent quality even under long-term operation.

4.2 Designed specifically for high-security fencing manufacturing

Unlike ordinary mesh welding equipment, this fully automatic transparent fence welding machine focuses on:

Extremely fine vertical line spacing, eliminating footholds and making it difficult to climb

High-strength welding, resistant to cutting and vandalism

Robust machine construction ensuring long-term precision

Reduced reliance on manual labor

This makes the machine ideal for transparent fence panel manufacturers in residential, industrial, and government security projects in South Africa and Zimbabwe.

4.3 Scalable solutions to help fence manufacturers grow

Whether you are upgrading an existing fence factory or building a new production line, we offer fully automated clear view fence production lines that can be equipped with automated stacking systems to reduce manual handling costs.

The flexibility and reliability of the DAPU anti-climb fence panel welding machine help manufacturers expand production while maintaining consistent product quality.

4.4 South Africa clear view fence machine video:

5. Why Choose Our Clear View Fence Welding Machine for South Africa Market

Choosing the right clear view fence welding machine is critical for manufacturers supplying the South African security fencing market, where project standards, durability requirements, and delivery reliability are strictly evaluated.

Our machines are designed specifically to support long-term, high-security fence production for professional manufacturers rather than short-term, low-cost output.

5.1 Designed for South African Clear View Fence Standards

South Africa’s Clear View Fence projects require strict control over wire spacing, welding strength, and panel flatness.

Our automatic clear view fence welding machine is configured to match common South African specifications, helping manufacturers consistently meet project and tender requirements.

This reduces panel rejection rates and improves overall production reliability.

5.2 Stable Welding Performance for High-Security Applications

Security fence panels must maintain strength over long service periods.

Our high security fence welding machine uses a stable welding system designed for continuous operation, ensuring:

- Uniform weld points

- Consistent penetration strength

- Reliable performance under long working hours

This level of stability is essential for anti-climb fence production used in residential estates, industrial zones, and infrastructure projects.

5.3 Heavy-Duty Machine Structure for African Working Conditions

The machine frame and mechanical structure are built for industrial environments common in South Africa, including high workload and extended production cycles.

Compared with light-duty equipment, our design focuses on:

- Structural rigidity

- Long-term accuracy

- Reduced vibration during welding

This makes the machine suitable for factories aiming for stable output and long service life.

5.4 Reduced Labor Dependency and Operating Cost

Automation significantly reduces reliance on skilled manual labor.

With precise wire feeding and welding control, manufacturers can maintain consistent quality while lowering labor cost per panel.

This advantage becomes increasingly important as local labor costs and production pressure rise.

5.5 Export Experience and Technical Support for Africa

We have experience supplying clear view fence welding machines to African markets, with solutions adapted to local power conditions and production requirements.

Support includes:

- Machine installation guidance

- Operator training support

- Long-term spare parts supply

This ensures manufacturers in South Africa can operate their anti climb fence panel machine with confidence and minimal downtime.

By choosing a clear view fence welding machine designed for the South African market, manufacturers gain not only equipment, but a reliable production solution that supports long-term business growth.

6. Clear View Fence Machine for Zimbabwe Security Fence Projects

In Zimbabwe, Clear View Fences are increasingly specified for security fence projects where durability, strength, and long service life are critical.

These projects are commonly associated with mining operations, government facilities, industrial zones, and infrastructure protection.

To meet these demands, manufacturers require a clear view fence welding machine that delivers stable quality while remaining cost-effective and easy to operate.

6.1 Security Fence Requirements in Zimbabwe Market

Zimbabwean security fence projects often focus on:

- Strong anti-climb and anti-cut performance

- Long-term outdoor durability

- Consistent panel quality across large project volumes

An automatic clear view fence welding machine helps manufacturers achieve uniform welding strength and precise wire spacing, ensuring panels meet inspection and acceptance standards.

6.2 Practical and Reliable Production for Local Manufacturers

Unlike highly customized niche markets, many Zimbabwe projects prioritize reliability and stable output over unnecessary complexity.

Our high security fence welding machine is designed to:

- Operate reliably with local power conditions

- Maintain consistent welding performance

- Reduce dependence on highly skilled operators

This makes the anti climb fence panel machine suitable for both established fence factories and growing manufacturers entering the security fencing sector.

6.3 Cost-Controlled Solution for Project-Based Production

Budget control is a key factor in Zimbabwe’s security fencing projects.

By improving automation and reducing labor input, manufacturers can lower production cost per panel while maintaining required security standards.

This balance between cost and quality allows suppliers to compete effectively for tender-based and contract-driven projects.

6.4 Supporting Long-Term Security Fence Manufacturing

For manufacturers supplying Zimbabwe’s security fence market, equipment stability and after-sales support are essential.

A well-designed clear view fence welding machine provides:

- Stable production over long operating hours

- Reduced maintenance interruptions

- Consistent output for repeat projects

This enables manufacturers to build long-term partnerships with project contractors and government clients.

7. Typical Applications of Clear View Fence Panels

Clear View Fence panels are widely used in high-security environments where visibility, strength, and anti-climb performance are essential.

In South Africa and Zimbabwe, these panels have become a standard solution for both public and private security fencing projects.

7.1 Residential and Gated Community Security Fencing

Clear View Fence panels are commonly installed around:

- Gated residential estates

- Apartment complexes

- Private housing developments

The anti-climb design and clean appearance provide strong security protection without blocking visibility, making them ideal for residential security fencing.

7.2 Industrial and Commercial Perimeter Protection

Factories, warehouses, and logistics centers require fencing that offers long-term durability and reliable protection.

Clear View Fence panels produced by a clear view fence welding machine are widely used for:

- Industrial parks

- Distribution centers

- Commercial facilities

Their rigid structure and strong welds help protect valuable assets and equipment.

7.3 Mining Sites and Resource Facilities

Mining operations in Southern Africa often require high-security fencing capable of withstanding harsh environments.

Clear View Fence panels are used for:

- Mine site perimeter security

- Equipment storage areas

- Restricted access zones

In these applications, consistent panel strength produced by a high security fence welding machine is critical for safety and compliance.

7.4 Government, Infrastructure, and Public Facilities

Clear View Fence systems are frequently specified for:

- Power substations and utilities

- Water treatment plants

- Schools, hospitals, and public institutions

- Border and infrastructure protection

The anti-climb and anti-cut performance of these panels meets the strict security requirements of government and infrastructure projects.

7.5 Security Fence Projects Requiring High Visibility

In areas where surveillance and monitoring are essential, Clear View Fence panels provide:

- Clear sightlines for cameras and guards

- Strong physical protection

- Low maintenance over long-term use

This combination makes Clear View Fences a preferred choice for modern security fence projects across South Africa and Zimbabwe.

8. How to Choose the Right Clear View Fence Welding Machine?

Choosing the right clear view fence welding machine is a critical decision for manufacturers supplying high-security fence panels in South Africa and Zimbabwe.

The right machine ensures stable quality, efficient production, and long-term business competitiveness.

Below are the key factors manufacturers should consider before investing in an automatic clear view fence welding machine.

8.1 Required Wire Diameter and Fence Specification

Start by confirming the wire diameter range required for your target market.

Common Clear View Fence wire diameter: 3–6 mm

Panel height, width, and vertical wire spacing

Project or tender specifications

A suitable high security fence welding machine must handle these specifications without frequent adjustments or instability.

8.2 Mesh Accuracy and Wire Spacing Control

Clear View Fences rely on precise vertical wire spacing to prevent climbing.

Choose a machine that offers:

- Stable vertical and horizontal wire positioning

- Consistent mesh spacing across the entire panel

- Minimal deviation during continuous production

Poor wire spacing control can lead to panel rejection and failed inspections.

8.3 Welding System Stability and Strength

Welding quality directly affects the security performance of the fence panel.

When evaluating an anti climb fence panel machine, consider:

- Servo-controlled or transformer welding systems

- Consistent welding penetration

- Ability to operate continuously without overheating

Stable welding ensures each panel meets anti-climb and anti-cut requirements.

8.4 Production Capacity and Output Requirements

Define your required output in panels per hour based on order volume.

A properly selected automatic clear view fence welding machine should:

- Match your daily production targets

- Allow for future capacity expansion

- Maintain quality at higher speeds

Balancing output and quality is essential for project-based production.

8.5 Power Supply and Local Operating Conditions

Machines should be compatible with local power conditions in South Africa and Zimbabwe.

Important considerations include:

- Voltage and frequency compatibility

- Energy efficiency during long working hours

- Stable electrical control system

This reduces downtime and operational risk.

8.6 Level of Automation and Labor Dependency

Automation helps reduce reliance on skilled labor and improves consistency.

An effective high security fence welding machine should offer:

- Automatic wire feeding

- Automated welding cycles

- Simple operator interface

This allows factories to maintain stable production with fewer operators.

8.7 Technical Support and Long-Term Reliability

Beyond machine specifications, consider the supplier’s ability to provide:

- Installation and commissioning support

- Operator training

- Spare parts availability

A reliable supplier ensures your clear view fence welding machine continues to perform throughout its service life.

By carefully evaluating these factors, manufacturers can select a clear view fence welding machine that supports stable production, meets security standards, and enables long-term growth in the Southern African security fencing market.

9. Clear View Fence Welding Machine Supplier from China

When looking for a reliable clear view fence welding machine supplier, it is important to choose a manufacturer, not a trader. Direct manufacturers provide better technical support, consistent quality, and tailored solutions for your production needs.

9.1 Custom Solutions for the African Market

We understand the unique requirements of South Africa and Zimbabwe security fence projects. Our machines are designed to:

- Meet local mesh size and wire diameter standards

- Operate reliably under African power conditions

- Deliver high production efficiency for both small and large-scale manufacturers

Custom configurations ensure that your anti climb fence panel machine matches your exact project and tender specifications.

9.2 Installation and Training Support

To help you get started quickly and efficiently, we provide:

- On-site or remote machine installation guidance

- Operator training for smooth workflow

- Technical advice for optimizing production output and quality

This ensures your team can operate the machine confidently, even if it’s the first time handling automatic clear view fence welding machines.

9.3 Spare Parts Supply and Long-Term Support

We provide reliable spare parts supply for long-term operation, minimizing downtime and ensuring continuous production.

With our support, manufacturers in South Africa and Zimbabwe can maintain stable panel quality and meet the demands of high-security fencing projects.

9.4 Why Choose a Direct Manufacturer?

Working with a direct Chinese manufacturer offers clear advantages:

Consistent machine quality and welding performance

Access to customized solutions for regional projects

Long-term technical and parts support

This ensures your investment in a high security fence welding machine delivers maximum value over the years.

10. Request a Clear View Fence Production Solution

Are you ready to upgrade your security fence production and meet the growing demand for Clear View Fence panels in South Africa or Zimbabwe?

We provide professional solutions tailored to your factory’s needs, ensuring high-quality output, stable welding performance, and long-term reliability.

10.1 How We Can Help?

Get clear view fence machine configuration advice

Our engineers will recommend the most suitable machine model and setup based on your project specifications, panel size, and production volume.

Discuss your security fence project

Share your project requirements with us, and we’ll help you design a production solution that meets local standards and tender requirements.

Request a production line solution for South Africa

Whether you need a single machine setup or a fully automatic production line, we can provide a solution optimized for your factory and the Southern African market.

10.2 Why Contact Us Today?

Direct manufacturer, not a trader – guaranteeing consistent quality

Machines tailored for African standards and power conditions

Full support including installation, operator training, and spare parts supply

Take the first step toward reliable, high-efficiency Clear View Fence production by contacting us today.

Your next high-security fence project starts with a smart production solution.

Clear view fence machine: https://www.wire-mesh-making-machine.com/358-security-fence-welding-machine-product/

Post time: Feb-11-2026