Reinforcing Mesh Welding Machine

Pre-cut Reinforcing Wire Mesh Welding Machine Line

· 4-12mm wire diameter workable;

· 80-100 times/ min welding speed;

· European design

DAPU factory is a gold manufacturer of reinforcing mesh welding machines in China. We have more than 30 years of production experience. To provide customers with better solutions, we have integrated European welding technology, faster and more efficient welding mesh, and famous foreign electronic components are also used to achieve the purpose of fewer failures and long service life of the machine.

Reinforcing Mesh Welding Machine Advantages:

1. Easier machine maintenance, fewer machine problems.

2. Same welding pressure for each welding point, guaranteeing welding quality.

3. Enough welding power to weld max.12mm rebar.

4. The welding speed can be up to a max of 80-100 times/min.

5. Easily adjust the line wire space. For the welding electrode no need to work; only need to disconnect the electromagnetic valve.

6. Precision pressure reduction valve, ±0.5 error. High flow.

Reinforcing Mesh Welding Machine Parameter:

| Model | DP-GW-2500B |

| Wire diameter | 4-12mm |

| Line wire space | 100-300mm |

| Cross wire space | 50-300mm |

| Width of mesh | 1200-2500mm |

| Length of mesh | 1.5-12m |

| Welding electrodes | 24pcs |

| Welding transformer | 150kva*12pcs |

| Welding speed | Max 80-100 times/min |

| Line wire feeding | Pre-straightened&pre-cut |

| Cross-wire feeding | Pre-straightened&pre-cut |

| Air compressor | Less than 3.7m^3/min |

| Weight | 7.3T |

| Machine size | 22*3.5*2.3m |

Video of Fully Automatic Reinforcing Mesh Welding Machine

Watch the DAPU fully automatic reinforcing mesh welding machine production line in operation! This video visually demonstrates how our advanced fully automatic welded mesh production line achieves fully automated production from raw materials to finished mesh sheets.

Automatic welding system: Precisely controls each weld point, ensuring strong welds without any missed welds or weak welds.

Servo mesh pulling system: Achieves mesh size accuracy of ±1mm; mesh size can be changed on the touchscreen, greatly improving production flexibility.

Automatic flipping and dropping: Ensures that the welded reinforcing mesh sheets are accurately flipped and dropped into position.

Automatic transport system: Outputs the stacked reinforcing mesh sheets. No manual handling required.

This fully automatic reinforcing mesh welding machine is designed for modern reinforcing steel processing enterprises that pursue high efficiency, low energy consumption, and high quality.

Why Choose the DAPU Reinforcing Mesh Welding Machine?

DAPU reinforcement mesh panel welder DP-GW-2500 B is jointly developed with the European technical team.

The line wire feeding car is controlled by a servo motor, which saves time and provides precise feeding.

Welding part, we equipped SMC (Japan) customized 90 multi-force air cylinder, Output power increased by 20%, Air consumption saves 30%.

The mesh pulling system is equipped with a Panasonic servo motor, pulling speed is faster, and the pulling distance is more accurate.

The mesh falling part has an automatic falling and pulling out device. This is an optional device.

DAPU reinforcing mesh welding machine, with European design and Chinese price.

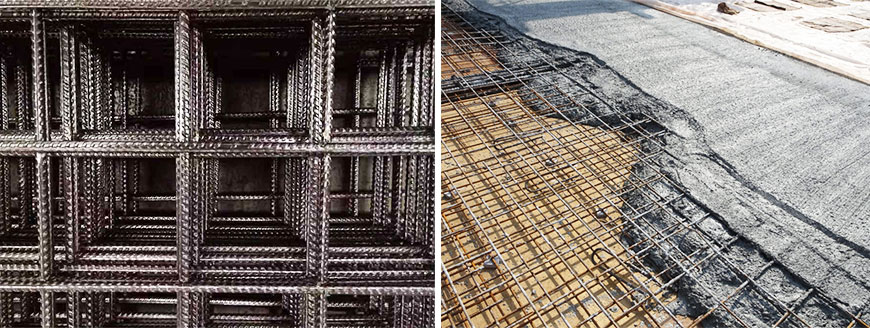

Reinforcing Mesh Application:

Reinforcement mesh is mainly used in building reinforcement and construction. Reinforcement mesh should have good adhesion with concrete grouting. Therefore, it is not recommended to use oily substances and paint on steel mesh. To prevent corrosion of steel structures, they should be installed completely immersed in concrete.

Residential and commercial buildings: Reinforced concrete slabs, floors, ground surfaces, shear walls, basement walls, and foundation slab reinforcement.

Road and pavement engineering: 8-12mm heavy-duty steel mesh is typically used for urban roads, highways, and airport runways due to its high load-bearing capacity and crack prevention; 5-6mm standard construction steel mesh is used for plazas and sidewalks; it is also used in bridge structures, pipelines, and other concrete engineering projects.

Other applications: 5-6mm mesh is used in tunnels, mines, and slope protection projects to improve tensile strength and stability. It is also used for construction site fencing or temporary protective barriers.

Sales-after Service of Reinforcing Mesh Welding Machine

Welcome to the DAPU factory

- We welcome global customers to schedule a visit to DAPU's modern factory. We offer comprehensive reception and inspection services.

- You can initiate the inspection process before equipment delivery to ensure that the fully automatic reinforcement mesh machine you receive fully meets your standards.

Providing guidance documents

- DAPU provides operation manuals, installation guides, installation videos, and commissioning videos for rebar mesh welding machines, enabling customers to learn how to operate the fully automatic wire mesh welding machine.

Overseas installation and commissioning services

- DAPU will dispatch technicians to customer factories for installation and commissioning, train workshop workers to operate the equipment proficiently, and quickly master daily maintenance skills.

Regular overseas visits

- DAPU's highly skilled engineering team visits customer factories overseas annually to maintain and repair equipment, extending equipment lifespan.

Rapid parts response

- We have a professional parts inventory system, enabling rapid response to parts requests within 24 hours, minimizing downtime, and supporting global customers.

Proven Success: Maximize Your ROI with DAPU Reinforcing Mesh Welding Machine

A Mexican customer's old AC reinforcing mesh welding machine suffered from excessive welding spatter, high energy consumption, and unstable current, leading to poor mesh quality. The customer purchased the DAPU 5-12mm reinforcing mesh welding machine DP-GW-2500B, equipped with a servo feeding and servo mesh pulling system. Furthermore, this equipment utilizes a medium-frequency inverter welding system, which not only improves mesh quality but also increases production efficiency. The customer reported a 40% increase in output; a 2.5-fold increase in electrode life; a 35% reduction in energy consumption; and an 18-month payback period. The customer was extremely satisfied.

Exhibition

DAPU's active presence at global trade shows showcases our strength as a leading wire mesh machinery manufacturer in China.

At the China Import and Export Fair (Canton Fair), we are the only qualified manufacturer in Hebei Province, China's wire mesh machinery industry, to participate twice a year, in both the spring and autumn editions. This participation symbolizes the nation's recognition of DAPU's product quality, export volume, and brand reputation.

In addition, DAPU participates in international trade shows annually, currently exhibiting in over 12 international markets, including the United States, Mexico, Brazil, Germany, the UAE (Dubai), Saudi Arabia, Egypt, India, Turkey, Russia, Indonesia, and Thailand, covering the most influential trade shows in the construction, metal processing, and wire industries.

Certification

DAPU wire mesh welding machines are not merely high-performance rebar mesh production equipment, but also a showcase of innovative technology. We hold CE certification and ISO quality management system certification, meeting stringent European standards while adhering to the highest international quality management standards. Furthermore, our rebar mesh welding machines have been applied for design patents and other technical patents: Patent for a Horizontal Wire Trimming Device, Patent for a Pneumatic Diameter Wire Tightening Device, and Patent certificate for a Welding Electrode Single Circuit Mechanism, ensuring you purchase the most competitive and reliable rebar mesh welding solution on the market.

FAQ

Q: What are the maximum and minimum welding diameters of the DAPU reinforcing mesh welding machine? Can it handle all wire diameter combinations in the range of 5mm to 12mm?

A: The maximum weldable rebar diameter is 12mm+12mm, and the minimum is 5mm+5mm, without issues of weak welds or over-welding.

Generally, it can, but you should consult a DAPU engineer regarding the maximum permissible difference between the warp and weft wires to avoid excessive heat erosion of the thinner rebar by the thicker rebar or insufficient weld strength.

Q: Is the DAPU reinforcing mesh welding machine equipped with a medium-frequency inverter (MFDC) or a low-frequency (AC) welding system? Which is more suitable for producing high-quality mesh?

A: The DAPU pneumatic reinforcing mesh welding machine is equipped with a medium-frequency inverter (MFDC) welding system. Welding thicker rebar requires a larger current and more precise heat control; when welding thinner rebar, MFDC can quickly and accurately stop the current, avoiding damage to the wire due to overheating and resulting in sparks.

Q: How many panels can be produced in one day for the reinforcing mesh welding machine?

A: The production is not only related to the welding speed. It is also different from the mesh opening and mesh length you want.

Such as for 8mm wire, 150*150mm opening, 2.5*6m mesh, it is about 360-400pcs/day;

If 8mm wire, 100*100mm opening, 2.5*6m mesh, it will be about 280-300pcs/day.

Q: What is the price of the DAPU reinforcing mesh welding machine?

A: The price of the DAPU reinforcing mesh welder is not fixed and varies depending on the customer's customised requirements. Factors such as the type of reinforcing steel, wire diameter, width of the reinforcing mesh, required level of automation, and configuration of electronic components all contribute to the price difference.

Q: What is the maximum width of the reinforcing mesh produced by the DAPU reinforcing mesh welding machine?

A: The maximum width is 3000mm, but it can be customised according to customer requirements.

Q: What are the maximum and minimum mesh sizes for the reinforcing mesh produced by the DAPU reinforcing mesh welding machine? Does it support quick changes in mesh size?

A: The maximum mesh size is 300x300mm, and the minimum can be 50x100mm.

Yes, it supports this. DAPU's modern reinforcing mesh welder is highly flexible and allows for rapid adjustments. Adjusting the weft wire spacing: Simply input the new weft wire spacing on the HMI or touchscreen to adjust the high-precision servo motor-driven mesh-pulling trolley. The warp wire spacing: Quickly change the warp wire spacing by releasing and locking the feed trolley's wire inlet device and electrode arm.

Q: Can the DAPU reinforcing mesh welding machine handle cold-rolled ribbed steel bars and hot-rolled plain round steel bars?

A: Yes, it can.

Q: What is the error range of the reinforcing mesh produced by the DAPU reinforcing mesh welding machine, and how is dimensional accuracy guaranteed?

The error range is ±2mm. The DAPU reinforcement mesh machine uses a high-precision servo feeding system and a servo mesh-pulling system, which can accurately control the error range, and the finished mesh meets building code standards.

Q: How automated is the DAPU reinforcing mesh welding machine?

A: The DAPU steel bar mesh welding machine is an automated welding device. Workers need to insert the warp wires into the feed trolley. An automatic flipping system, a mesh dropping system, and an automatic transport system can be added according to the customer's automation requirements.

Q: What is the lifespan and replacement cycle of the electrodes for the DAPU rebar mesh welding machine? What are the costs and delivery times for consumable parts?

The welding electrodes for the DAPU rebar mesh welding machine are copper blocks, usable on all six sides, material: chromium zirconium copper. reducing the frequency and cost of electrode replacement. DAPU also provides a list of consumable parts to help customers plan costs and store spare parts. DAPU responds promptly to meet the supply needs for electrodes and other spare parts, supporting customers worldwide.

Q: Space needed for DAPU reinforcing mesh welding machine?

A: Whole production line with automatic mesh falling system, around 28m in length, 9m in width.

Q: How about your guarantee for the reinforcing mesh welding machine?

A: One or two years since the machine was installed at the buyer's factory, but within 18 months from the shipment date.

Q: What kind of after-sales service and technical support does DAPU provide for reinforcing mesh welding machines?

A: DAPU offers both online and offline service support.

Online Service Support:

1. Provides installation videos, operation manuals, equipment layout diagrams, and other guidance documents.

2. Supports 24-hour service to quickly resolve equipment problems for customers.

Offline Service Support:

1. Supports overseas installation and commissioning services, quickly installing and commissioning equipment for production.

2. Provides free training for workshop workers to enable them to operate, maintain, and troubleshoot equipment proficiently.