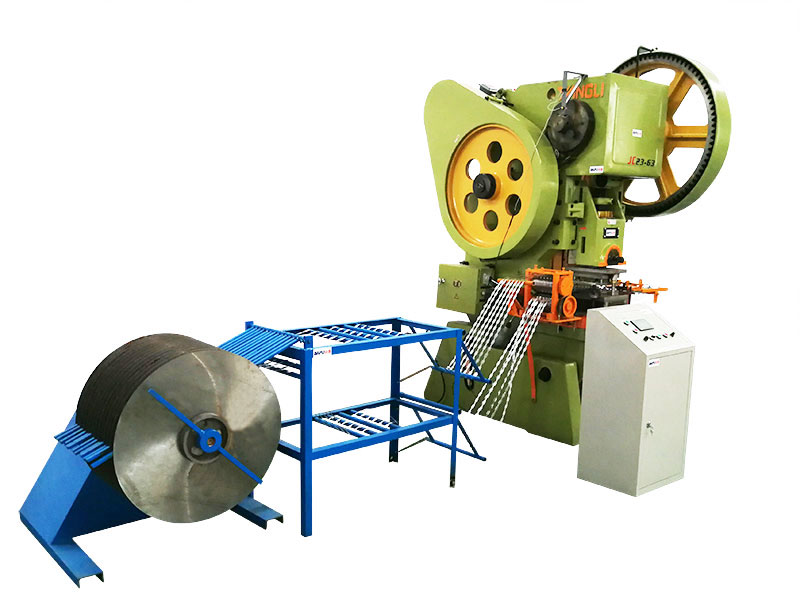

Concertina Razor Barbed Wire Machine

Concertina razor barbed wire machine advantage

Automatic de-coiler holding max. 2 tons steel sheet.

We adopt the Chinese No. 1 Yangli brand Pressing machine

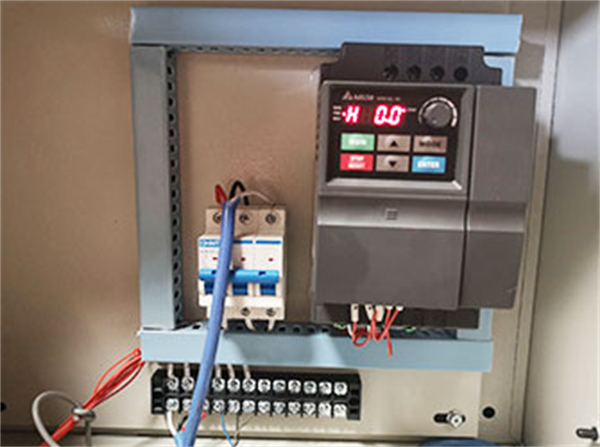

Touch screen + PLC control + Delta inverter, easy operation.

The lubricant oil device is a visible and central process, maintaining the machine easily, extending machine life.

Razor coiling machine adopts an inverter to adjust working speed, be more precise, and have a longer life.

Razor coiling machine adopts Grid counter to record loop quantity automatically.

Concertina razor barbed wire machine parameter

|

Model |

25T |

40T |

63T |

Coiling machine |

|

Voltage |

3phase 380V/220V/440V/415V, 50HZ or 60HZ |

|||

|

Power |

2.2kw |

4kw |

5.5kw |

1.5kw |

|

Producing speed |

70 times/min |

75 times/min |

120 times/min |

3-4 Ton/8h |

|

Pressure |

25Ton |

40Ton |

63Ton |

-- |

|

Material thickness and wire diameter |

0.5±0.05(mm),according to customers' requirement |

2.5mm |

||

|

Material of sheet |

GI and stainless steel |

GI wire |

||

|

Weight |

2200kgs |

3300kgs |

4500kgs |

300kgs |

|

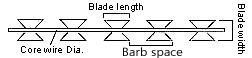

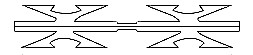

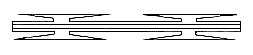

Type |

Barb Length |

Barb Width |

Barb Spacing |

Illustration |

|

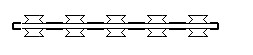

BTO-12-1 |

12±1mm |

13±1mm |

26±1mm |

|

|

BTO-12-2 |

12±1mm |

15±1mm |

26±1mm |

|

|

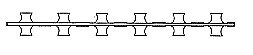

BTO-18 |

18±1mm |

15±1mm |

33±1mm |

|

|

BTO-22 |

22±1mm |

15±1mm |

34±1mm |

|

|

BTO-28 |

28±1mm |

15±1mm |

48±1mm |

|

|

BTO-30 |

30±1mm |

18±1mm |

49±1mm |

|

|

BTO-60 |

60±1mm |

32±1mm |

96±1mm |

|

|

BTO-65 |

65±1mm |

21±1mm |

100±1mm |

|

How does the concertina razor barbed wire machine working?

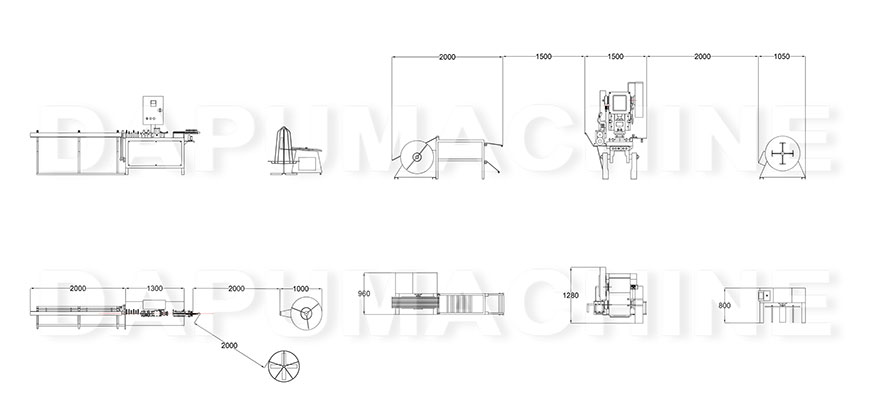

Concertina razor barbed wire machine line layout:

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine |

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Concertina razor barbed wire application

The concertina razor barbed wire is used in:

Cattle farms fence and agricultural lands (especially the barbed type);

Military areas (garrisons, military centers, and other protected areas);

Demarcation of private gardens and villas;

Protection of unfinished structures;

Airports and areas that need to be protected with higher fences.

FAQ

Q: What are the accepted payment methods?

A: T/T or L/C is acceptable. 30% in advance, we start produce machine. After machine finished, we will send you testing vide or you could come to check machine. If satisfied with machine, arrange balance 70% payment. The we can loading machine to you.

Q: How to transport different type of machine?

A: Normally 25T and 40T type need one 20GP container. 63T machine need one 40GP container

Q: The production cycle of the razor barbed wire machine?

A:30-45days

Q: How to replace worn parts?

A: We have free spare part box loading together with machine. If there is other parts needed, normally we have stock, will send to you in 3 days.

Q: How long is the warranty period of the razor barbed wire machine?

A: 1 year after the machine arrive in your factory. If the main part broken because of quality, not manually mistake operation, we will send you replace part for free.

Q: Can I make all type of blade on one machine?

A: Different type of machine fit to different blade. Similar type can made by one machine, just need to change the mold.

Q: Do you have clips and tools?

A: Yes, we provide the whole line.